Facilities

The department has approximately 12,000 square feet of laboratory space for the following laboratories: Robotics and Automation, Controls and Mechatronics, Instrumentation and Data Acquisition, Manufacturing, Precision Measurement, Thermo/Fluids, Design, Student Projects, Student Research, and research labs. The laboratories are used to support undergraduate instruction, undergraduate research, student design projects, and faculty research.

Mechanical Engineering Facilities

The Mechanical Engineering Department offers students well-equipped teaching, design, and research laboratories, though all of them are more or less used for mixed purposes as discussed below. All students get firsthand experience using the equipment.

Manufacturing Lab (room 133)

This introduces students to lathes, milling machines, injection modeling, numerically controlled machining, 3D printing, and many other manufacturing processes during the sophomore course ME 210 Manufacturing and Design. The students apply this knowledge in the construction of their projects for ME 497/8 Senior Design Project I/II. The wide array of equipment is specifically for student use. There is a separate machine shop designated for the professional technicians of the Engineering Division.

Senior Projects Lab (room 134)

This serves as an assembly and work area, including two welding stations, for ME senior design projects. Students work in teams on capstone projects, designing and building everything from robotic fish to music synthesizers to medical devices to Formula SAE racecars to rockets. Adjacent to this space are two faculty research labs: one focused on alternative energy and wind turbine design; and one on smart materials and design of medical devices:

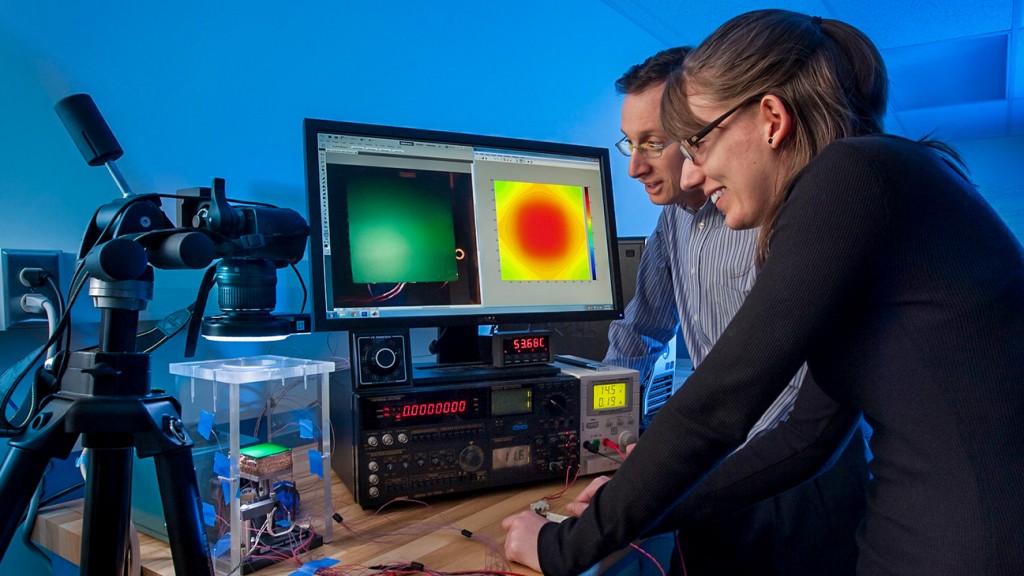

Smart Material Architectures, Characterization, and Design Laboratory (Room 134a)

This lab includes many customized instruments (co-designed by faculty and students) for experimentally investigating and characterizing smart material actuators and sensors that have applications in robotics and medical devices, among other areas. Lab PI: Prof. Brent Utter

Mechanical Design Lab (room 135)

This contains 18 networked Dell workstations, including one for an instructor with screen projection. Design software packages include CAD, CAM, and CAE such as Inventor, ADAMS, AutoCAD, LabView, and Virtual Gibbs. Analysis packages include ANSYS, Fluent FlowLab, Engineering Equation Solver, Matlab, MathCad, and Mathematica. Supporting software includes word processors, spreadsheets, and Internet access. Located next to the Manufacturing Lab, the Mechanical Design Lab integrates computer-based design and analysis with an emphasis on manufacturing.

Thermal/Fluids Lab (room 136)

This serves ME 475 Thermal/Fluid Systems. Major equipment includes a subsonic wind tunnel, boundary layer wind tunnel, refrigeration loop and heat exhangers, steam turbine/generator, gas turbine turbojet engine, internal combustion engines, among other equipment. This space also houses a faculty research lab for hypersonic fluid mechanics for aerospace applications, directed by Prof. Toby Rossmann. The hypersonic expansion tube facility was designed, built, and used for experiments with undergraduates, and includes laser-based flow instrumentation supported by the National Science Foundation.

Control Systems Lab (room 234)

This serves ME 480 Control Systems and Mechatronics Design and Analysis. Six benches are each equipped with a rotational servomechanism, computer, programmable logic controller, digital storage oscilloscope, multimeter, power supply, pulse-width modulated amplifier, function generator, and an electronics workstation on which both analog and digital circuits are built. The system allows for the analysis and evaluation of control algorithms.

Biomechanics Lab (room 236)

The room contains an eight-camera image system and software for studying human motion that was partially funded by a $213,610 National Science Foundation grant. This system gives the ability to comprehensively quantify the complex kinematics and kinetics necessary to produce a motion.

Instrumentation Lab (room 238)

This serves ME 331 Instrumentation and Data Acquisition. Six benches are each equipped with a computer containing a data acquisition board, a digital storage oscilloscope, multimeter, power supply, frequency counter/timer, and function generator. Further lab capabilities include pressure and temperature measurement, strain gauge application, and fractional horsepower motor testing with an eddy current dynamometer.

Water channel for Undergraduate Turbulence Research (room 106)

The Water Channel facility is a faculty research lab for Prof. Dan Sabatino. Facility was designed and built with Lafayette undergrads, and many students perform research here.

Vehicle Dynamics and Control Research Laboratory (room 106B)

This lab includes a student-designed and -built driving simulator used for research on vehicle control led by Prof. Alex Brown.